14"X1" 5p Snail Lock Resin Diamond Pad Edge Polishing Abrasives

-

Price:

Negotiable

- minimum:

- Total supply:

-

Delivery term:

The date of payment from buyers deliver within days

-

seat:

Zhejiang

-

Validity to:

Long-term effective

-

Last update:

2017-12-23 02:02

-

Browse the number:

199

Company Profile

Company Profile

By certification [File Integrity]

Contact:Miss Cindy Fu(Mr.)

Email:

Telephone:

Phone:

Area:Zhejiang

Address:Zhejiang

Website: http://yinding.liyangyacht.com/

Product Details

1.Technological Paramter:

Colour: Brown, gray(black), white, red, green

Size: 4"-20"

Width: 1"-3"

Density: 3P-12P

Grit: 120#-320#

Abrasive: Aluminium oxide, green/black silicon carbide, white aluminium oxide

2.Feature

(1). Brown

Abrasive: Aluminium oxide

Cutting power for aluminum castings, hand tools, knives, stainless steel iron products, such as the modification of metal workpieces and grinding, metal cleaning rust, welding point of the clean-up, modification of a variety of castings, cast grinding, the edges to remove the castings excellent results.

(2). Gray/ black

Abrasive: Silicon carbide

Cutting power for aluminum castings, hand tools, knives, stainless steel iron products, such as the modification of metal workpieces and grinding, metal cleaning rust, welding point of the clean-up, modification of a variety of castings, cast grinding, the edges to remove the castings excellent results.

(3). Red/white

Abrasive: White aluminium oxide

Workpiece for electroplating metal wire drawing processing, drawing fast, the Silk Road clear, effective, no residue, no black. Of zinc alloy, chrome-plated hard texture of the workpiece, such as the very strong performance. For copper wire drawing parts, need to select the soft round of the drawing, so as not to pull the bad parts; Nickel workpieces for wire drawing, the general hardness is usually the drawing round 5P; And chose thicker coating hardness for the drawing round 7P better (mainly for the lock-type). The edge of the drawing tool may be the hardness of sand for the 5P or 7P No. 240 # round the drawing. For aluminum products, recommend the use of pre-plated hardness of sand 7P No. 180 # -320 # for drawing the round.

(4). Green

Abrasive: Green silicon carbide

For applications that require precise and meticulous work, grinding does not produce smooth and left because of high-pressure spots, reduce defects, does not change the original weight of the workpiece, for stainless steel, titanium and other materials, such as insulating glass, cutlery, knives, first-class golf can play a very good effect. After grinding parabolic excellent brightness, it is to meet foreign requirements for the product brightness.

Colour: Brown, gray(black), white, red, green

Size: 4"-20"

Width: 1"-3"

Density: 3P-12P

Grit: 120#-320#

Abrasive: Aluminium oxide, green/black silicon carbide, white aluminium oxide

2.Feature

(1). Brown

Abrasive: Aluminium oxide

Cutting power for aluminum castings, hand tools, knives, stainless steel iron products, such as the modification of metal workpieces and grinding, metal cleaning rust, welding point of the clean-up, modification of a variety of castings, cast grinding, the edges to remove the castings excellent results.

(2). Gray/ black

Abrasive: Silicon carbide

Cutting power for aluminum castings, hand tools, knives, stainless steel iron products, such as the modification of metal workpieces and grinding, metal cleaning rust, welding point of the clean-up, modification of a variety of castings, cast grinding, the edges to remove the castings excellent results.

(3). Red/white

Abrasive: White aluminium oxide

Workpiece for electroplating metal wire drawing processing, drawing fast, the Silk Road clear, effective, no residue, no black. Of zinc alloy, chrome-plated hard texture of the workpiece, such as the very strong performance. For copper wire drawing parts, need to select the soft round of the drawing, so as not to pull the bad parts; Nickel workpieces for wire drawing, the general hardness is usually the drawing round 5P; And chose thicker coating hardness for the drawing round 7P better (mainly for the lock-type). The edge of the drawing tool may be the hardness of sand for the 5P or 7P No. 240 # round the drawing. For aluminum products, recommend the use of pre-plated hardness of sand 7P No. 180 # -320 # for drawing the round.

(4). Green

Abrasive: Green silicon carbide

For applications that require precise and meticulous work, grinding does not produce smooth and left because of high-pressure spots, reduce defects, does not change the original weight of the workpiece, for stainless steel, titanium and other materials, such as insulating glass, cutlery, knives, first-class golf can play a very good effect. After grinding parabolic excellent brightness, it is to meet foreign requirements for the product brightness.

| Size | Density | Grit | Single weight | QTY | Export Carton Size | CBM | GW | NW | ||

| G/pc | Length | width | highth | kgs | kgs | |||||

| 14"x1" | 12P | 80#-320# | 2552 | 40 | 0.7 | 0.36 | 0.51 | 0.1285 | 103 | 102 |

| 14"x1" | 9P | 80#-320# | 2042 | 40 | 0.7 | 0.36 | 0.51 | 0.1285 | 83 | 82 |

| 14"x1" | 7P | 80#-320# | 1701 | 40 | 0.7 | 0.36 | 0.51 | 0.1285 | 70 | 68 |

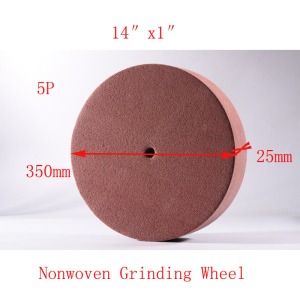

| 14"x1" | 5P | 80#-320# | 1225 | 40 | 0.7 | 0.36 | 0.51 | 0.1285 | 50 | 49 |

| 12"x1" | 12P | 80#-320# | 1875 | 40 | 0.62 | 0.32 | 0.51 | 0.1012 | 76 | 75 |

| 12"x1" | 9P | 80#-320# | 1500 | 40 | 0.62 | 0.32 | 0.51 | 0.1012 | 62 | 60 |

| 12"x1" | 7P | 80#-320# | 1250 | 40 | 0.62 | 0.32 | 0.51 | 0.1012 | 52 | 50 |

| 12"x1" | 5P | 80#-320# | 900 | 40 | 0.62 | 0.32 | 0.51 | 0.1012 | 38 | 36 |

| 10"x1" | 12P | 80#-320# | 1302 | 40 | 0.52 | 0.26 | 0.51 | 0.069 | 54 | 52 |

| 10"x1" | 9P | 80#-320# | 1041 | 40 | 0.52 | 0.26 | 0.51 | 0.069 | 43 | 42 |

| 10"x1" | 7P | 80#-320# | 868 | 40 | 0.52 | 0.26 | 0.51 | 0.069 | 37 | 35 |

| 10"x1" | 5P | 80#-320# | 625 | 40 | 0.52 | 0.26 | 0.51 | 0.069 | 27 | 25 |

| 8"x1" | 12P | 80#-320# | 833 | 40 | 0.42 | 0.22 | 0.51 | 0.0471 | 35 | 33.5 |

| 8"x1" | 9P | 80#-320# | 667 | 40 | 0.42 | 0.22 | 0.51 | 0.0471 | 28 | 27 |

| 8"x1" | 7P | 80#-320# | 556 | 40 | 0.42 | 0.22 | 0.51 | 0.0471 | 24 | 22 |

| 8"x1" | 5P | 80#-320# | 400 | 40 | 0.42 | 0.22 | 0.51 | 0.0471 | 18 | 16 |

| 6"x1" | 12P | 80#-320# | 469 | 60 | 0.47 | 0.165 | 0.51 | 0.0396 | 30 | 28 |

| 6"x1" | 9P | 80#-320# | 375 | 60 | 0.47 | 0.165 | 0.51 | 0.0396 | 24 | 22 |

| 6"x1" | 7P | 80#-320# | 313 | 60 | 0.47 | 0.165 | 0.51 | 0.0396 | 20 | 19 |

| 6"x1" | 5P | 80#-320# | 225 | 60 | 0.47 | 0.165 | 0.51 | 0.0396 | 15 | 14 |

| 4"x1" | 12P | 80#-320# | 208 | 80 | 0.22 | 0.22 | 0.51 | 0.0247 | 18 | 17 |

| 4"x1" | 9P | 80#-320# | 167 | 80 | 0.22 | 0.22 | 0.51 | 0.0247 | 15 | 14 |

| 4"x1" | 7P | 80#-320# | 139 | 80 | 0.22 | 0.22 | 0.51 | 0.0247 | 13 | 11 |

| 4"x1" | 5P | 80#-320# | 100 | 80 | 0.22 | 0.22 | 0.51 | 0.0247 | 9 | 8 |

| 100*15 | 12P | 80#-320# | 0.073 | 320 | 0.43 | 0.43 | 0.36 | 0.0666 | 24.5 | 23.5 |

| 100*15 | 9P | 80#-320# | 0.06 | 320 | 0.43 | 0.43 | 0.36 | 0.0666 | 20 | 19 |

| 100*15 | 8P | 80#-320# | 0.056 | 320 | 0.43 | 0.43 | 0.36 | 0.0666 | 18.75 | 18 |

| 100*15 | 7P | 80#-320# | 0.052 | 320 | 0.43 | 0.43 | 0.36 | 0.0666 | 17.8 | 16.8 |

| 100*15 | 6P | 80#-320# | 0.0484 | 320 | 0.43 | 0.43 | 0.36 | 0.0666 | 16.3 | 15.5 |

| 100*15 | 5P | 80#-320# | 0.04 | 320 | 0.43 | 0.43 | 0.36 | 0.0666 | 13.8 | 12.8 |